Manufacturers to buy Electroplating equipment is to help enterprises cast economic benefits, but electroplating automatic production line is not used or long-term use, electroplating equipment will cause different levels of damage. The price of new equipment is relatively expensive. If you always purchase new upgraded equipment to solve the problem of damage, it may cause great social and economic pressure to enterprises. Therefore, under the standard of ensuring normal production and processing operation, how to carry out maintenance and repair of equipment to reduce the production cost? Then we need to make clear the repair and maintenance, and extend the application period.

The maintenance of electroplating equipment includes the following aspects:

① Sound card frame repair and maintenance. Check the sound card frame on time to see if there is deformation on the surface of the stainless steel plate, whether the screws are loose, deficient and damaged after installation, and remove the dust on the surface to ensure the sound card frame is crisp and clean. After the plating surface solution has a relative effect.

② Crane maintenance and repair. First, check whether the equipment can work normally to see if it causes unusual noise, and adjust the brake pedal characteristics on time. For the tightness of the bearing with seat and the lubrication condition of the rolling bearing, the looseness needs to be tightened immediately, which in turn needs to be added with some proper lubricating grease.

③ Maintenance and repair of swing organization. Check the tightness and vibration of the reducer seat every relative time. If it causes serious damage, it needs to be replaced immediately.

④ Repair and maintenance of filter device of circulation system. In order to ensure the total flow of the filter press, it is necessary to clean or replace the filter element.

How to maintain electroplating equipment after long shutdown time?

If the equipment is not used for a period of time, it should be noted that the wooden floor can not be stored with water, and ensure that the address of the equipment is dry and natural ventilation. The motor of the equipment should be well maintained and wrapped with fresh-keeping paper. In order to avoid corrosion of rolling bearing, grease should be injected into the place where it is placed.

Test to restart electroplating equipment

If the equipment is not used for a long time, all the sealed fresh-keeping paper should be removed before restart to detect the contact condition between the parts. When the switch power cable is brittle, remember to carry out the disassembly and replacement, and test the screw tightness. The surface of stainless steel equipment should be removed in an all-round way to ensure that it is clean and beautiful. Then, the sensitivity of the detection equipment is detected when it is turned on.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

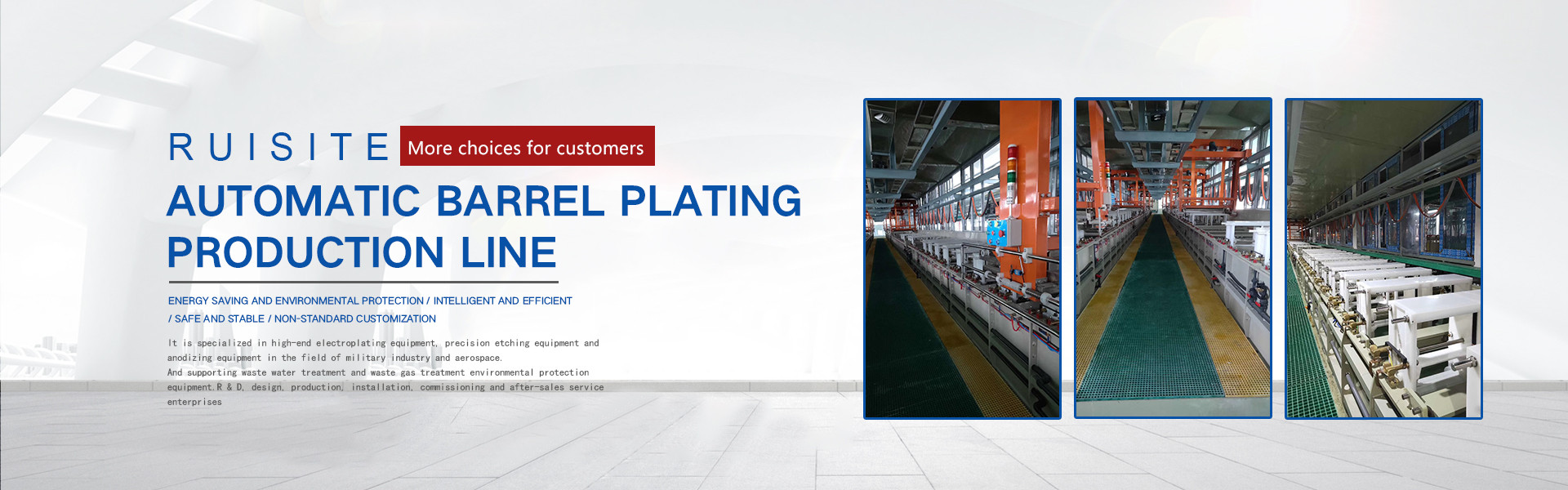

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

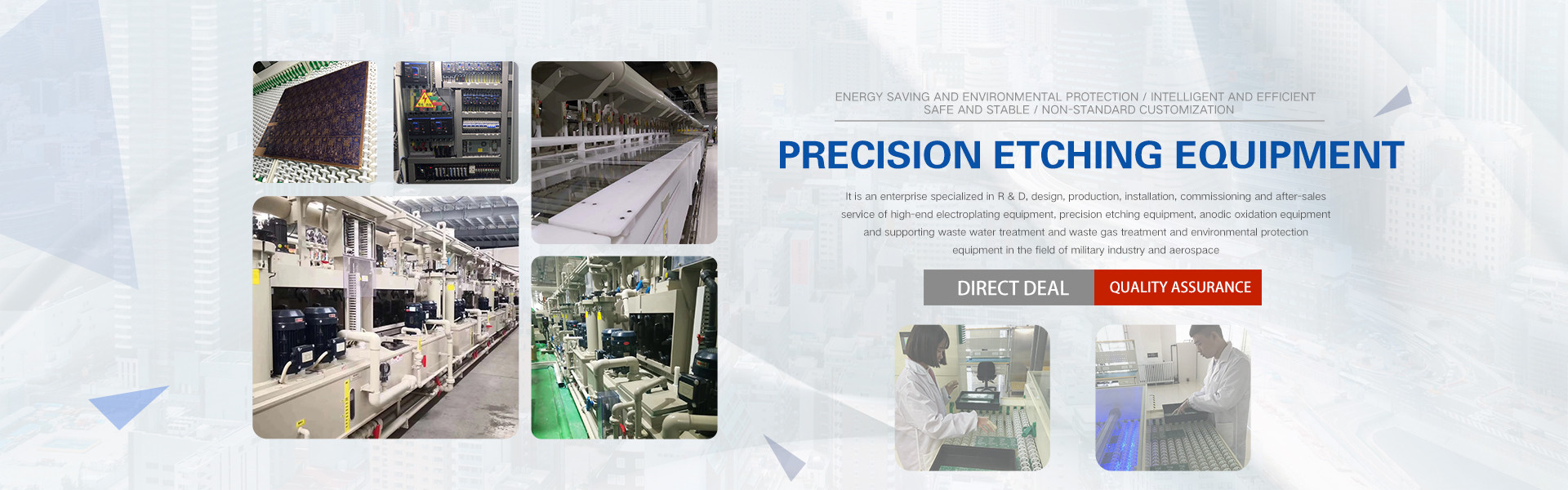

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡(jiǎn)體)

中文(簡(jiǎn)體)

Hot keywords