In order to make clear the difference between manual etching and etching by using etching machine, we should first find out what practical operation must be done by manual etching and etching machine etching, what special tools or etching machines must be used in this practical operation, and how much is the project investment cost and output?

Special tools for manual etching: air compressor is required for spraying; air compressor is used for baking; simple ceiling lamp is used for exposure; self-made plastic soaking pool is used for developing solution; self-made plastic soaking pool is used for etching; self-made plastic soaking pool is also used for stripping film. The total cost of this set of special tools to replace the etching machine is about 3000 yuan.

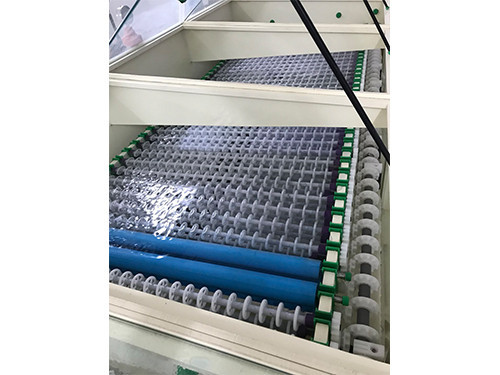

Special tools for etching machine: screen printing machine for spraying; electric oven for baking; exposure machine for exposure; developer for developing solution; etching machine and ultrasonic cleaning machine for stripping film. At least the project investment cost of this etching machine is about 15000 yuan.

Matching production: etching 200 * 300 mm size specification 0.5 mm thick stainless steel plate filter screen as an example

Manual etching must be five people, the output is about 16 pieces, and the commodity relativity is not smooth and defective;

Etching machine etching production and processing must be five people, the output is about 550 pieces, and the commodity relativity is more exquisite.

Summary difference:

According to the production capacity, we can get two differences between manual etching and etching machine etching. 1. Project investment cost; 2. Production and processing capacity

Application scope:

According to two differences, we can see that manual etching is suitable for small batch production and sample setting, while etching machine is suitable for mass production and processing.

- Home page

-

High end electroplating equipment

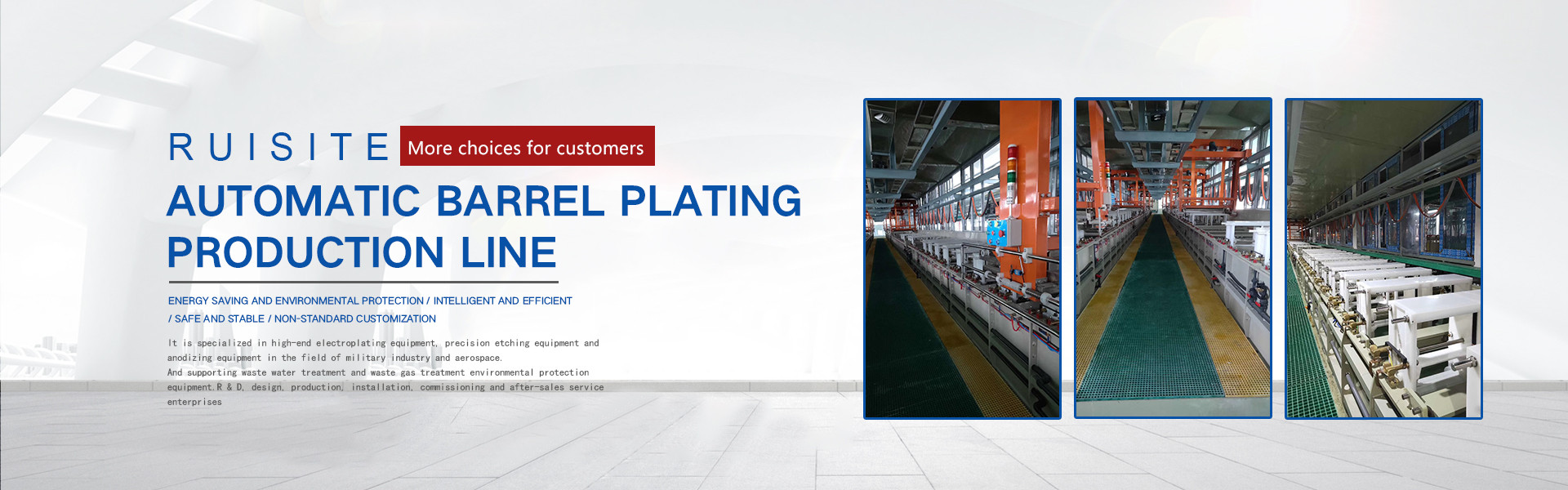

- Automatic galvanizing production line

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

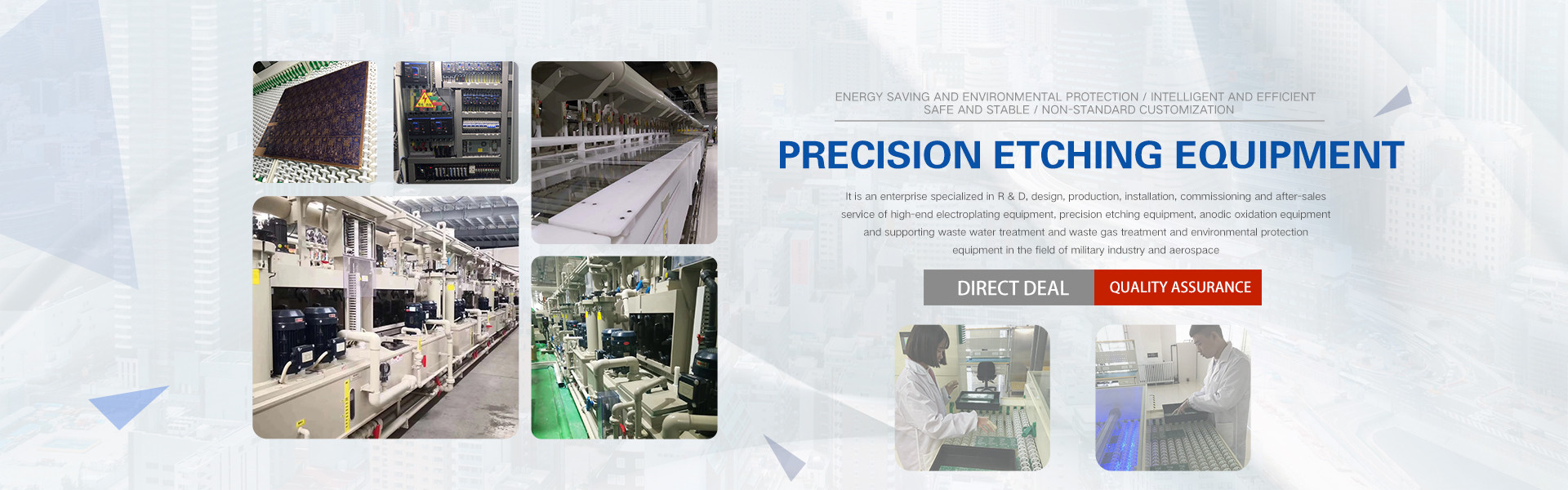

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords