In sheet metal etching machine, there are many factors that harm the actual effect of alkaline solution deoiling, which is more complex, but the key factor is whether the proportion of various components is effective in removing crude oil by partial alkali, the temperature of oil removal, the raw materials of deoiling products and the content of crude oil. In the whole process of deoiling, whether structural reinforcement measures are adopted and whether the oil removal time is sufficient.

1. Types and surface conditions of metal composite materials

In caustic soda solution deoiling, different metal composite products and workpieces need different machining process parameters.

2. In addition to the various components of hydraulic oil and its harm.

3. Operating temperature of hydraulic oil removal

Generally, the working temperature should not be too high. Under the premise of ensuring the actual effect and quality of degreasing, the higher the working temperature, the better. It can use a small amount of high efficiency surfactant to strengthen the whole process of wetting, infiltration and emulsion, reduce the temperature, and ensure the actual effect and quality of degreasing.

4. The perfect mechanism of deoiling

5. Degreasing time

Deoiling time depends on a variety of practical operating standards, which is the best caustic solution directly, especially the initial application of caustic soda solution has a very good effect, the time required is short.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

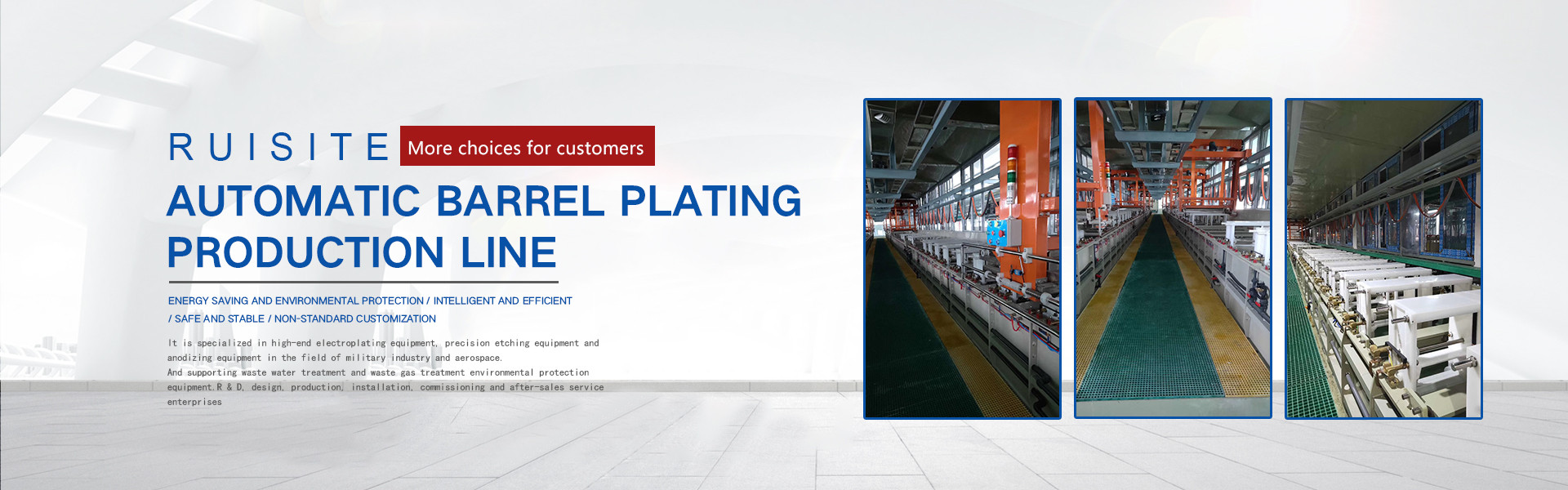

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

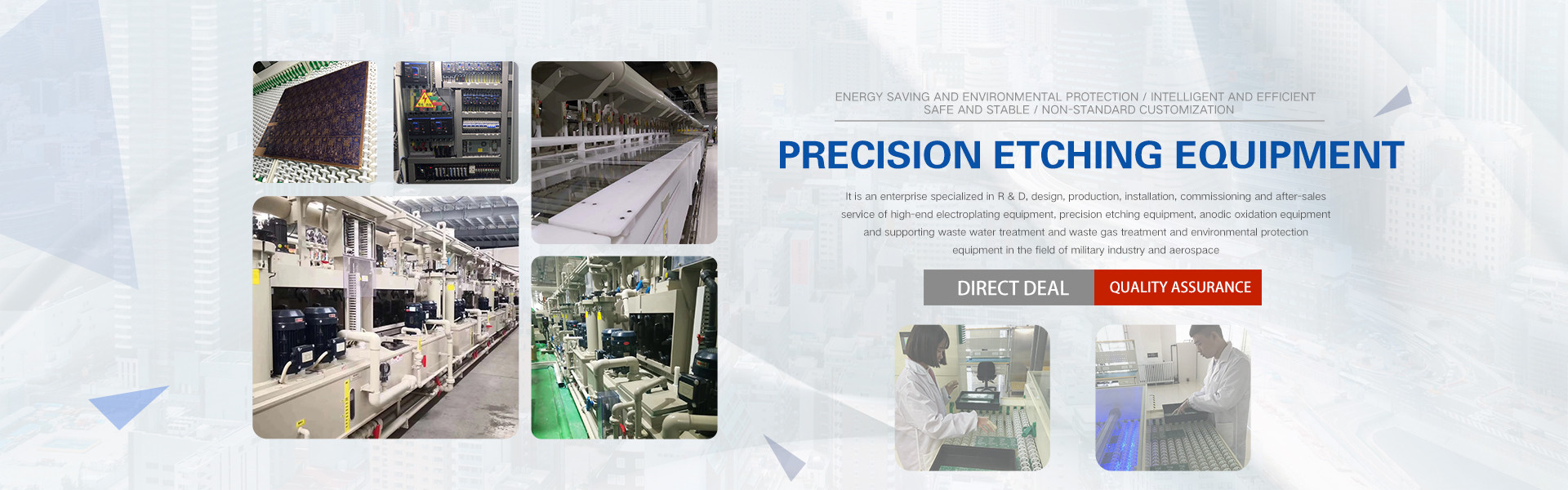

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords