The pH value is also very harmful to the characteristics of photoresist. Low pH value is beneficial to less side etching (higher etching index).

High pH value is generally for the hardware etching equipment manufacturers in terms of rapid etching. The system software is turned on every day, but the boards don't work continuously, so the water will be damaged by evaporation, but this kind of damage is far less than that obtained from nhoh plus liquid. Therefore, when the pH value is too high, it is necessary to increase the displacement, increase the copper composition or reduce the total alkalinity in the filling solution. High pH value is conducive to the dissolution of more copper. High pH will cause great side corrosion and damage the characteristics of some photoresists, especially the water-soluble photoresist, sodium hydroxide or NH4OH are usually added automatically by a pH magnetic induction automatic control system. Because of the water content of NH4OH, the water supplement must be stable to ensure that the added water is not easy to reduce the chloride ion content or copper concentration below their value.

When the pH value of alkaline etching solution is higher, some water-soluble resist will become soft and even stripped. Therefore, the lower pH value can be applied to the etching of fine routes. If the pH value is too high or low, be sure to reduce the exhaust pipe, reduce the copper composition, add sodium hydroxide or increase the total alkalinity in the filling solution. The pH value of aqueous solution is very important in the soluble manipulation, etching speed and side etching of copper. The NH4OH in the filling solution produced a lot of basic solutions that must maintain a pH value that is slightly alkaline (far more than 7.0), but the necessary sodium hydroxide provisions were added to achieve the highly recommended pH range (far higher than 7.0). Conversely, low pH is for slow etching. When there is no water in sodium hydroxide that will disturb the stability of the system software, nitrogen dioxide can work very well under the control of pH value, but it is very risky when applied. Therefore, high pH value of alkaline etching agent hardware etching equipment manufacturers generally used it in the production of production. However, for a given alkaline etching management system, the pH value must be higher than the limit (depending on the concentration of copper), in order to better maintain the copper salt composition in the etching machine aqueous solution.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

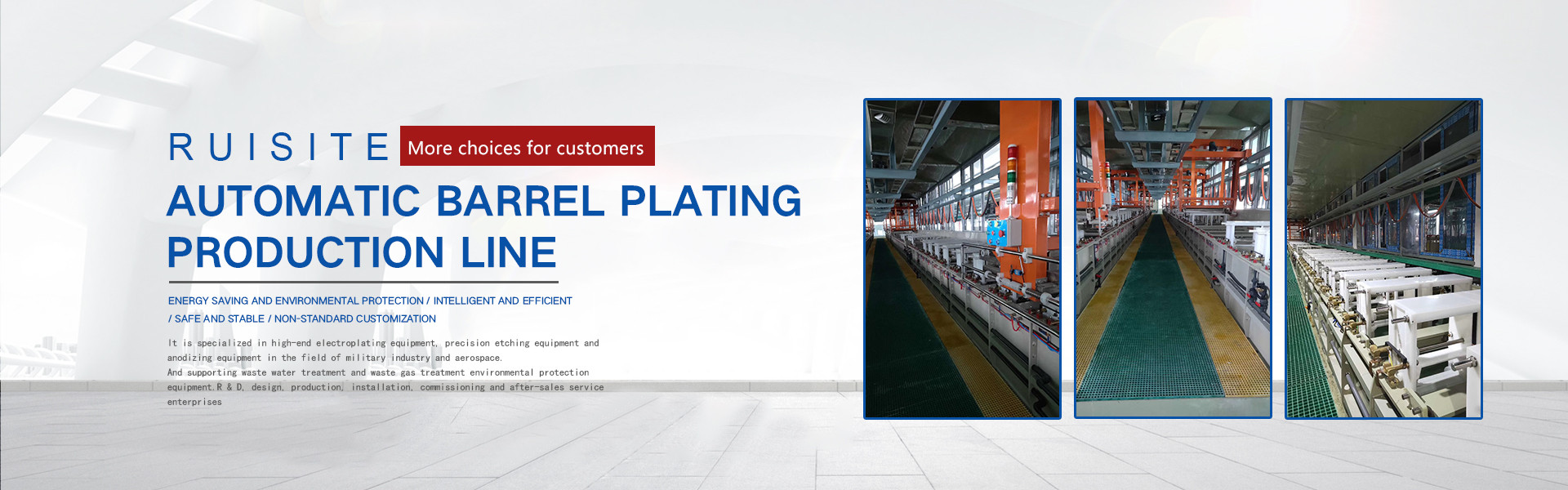

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

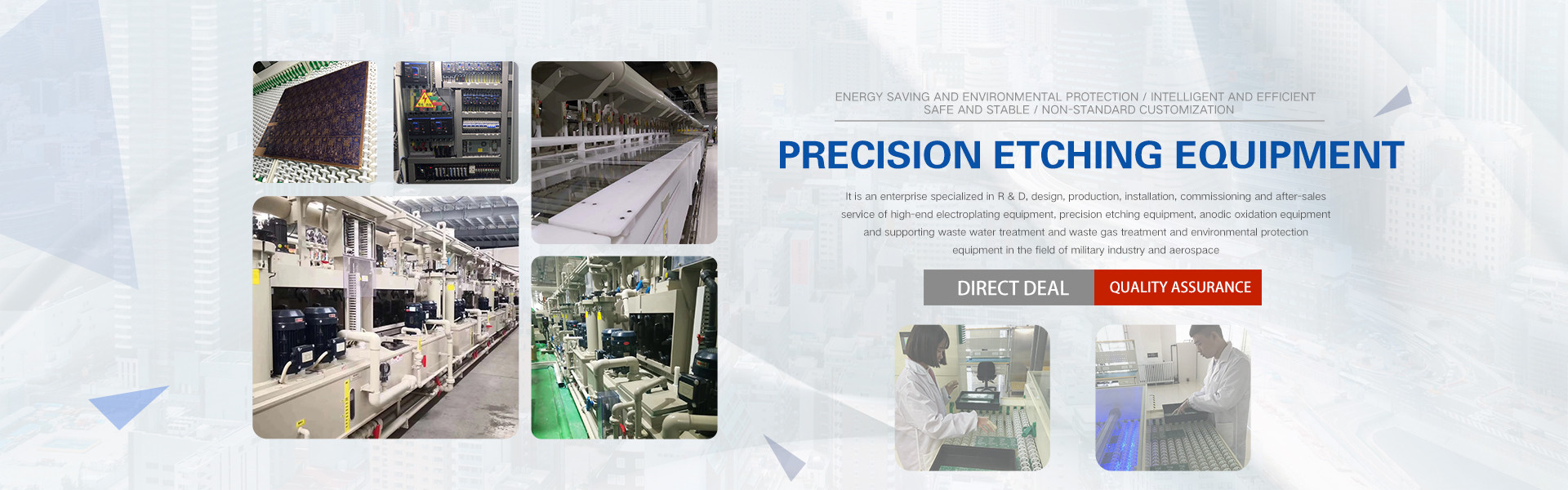

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords