Although many people have heard of the etching machine, they do not know which machine and equipment it belongs to and which main uses it has. Therefore, when they have to purchase the etching machine, they generally feel very confused. Even if they successfully buy back the machine and equipment, they do not know what the appropriate operation steps are, let alone other key points and problems, because there are many problems Pot friends do not know what the appropriate operating temperature is, so we will carry out a detailed introduction.

1. The temperature should not be too high

Some potters are not good at it, so they will deliberately raise the temperature during the construction of the project. They think that the working efficiency of the etching machine will be higher and higher, so as to achieve a more ideal etching actual effect. In fact, this is not the case. Too high temperature will always cause damage or etching problems, and even cause the situation that etching can not achieve success. It should be prevented from doing so.

2. That temperature suits Zui

If the operating temperature can not be too high, then which temperature is suitable for Zui? No matter what type and specification of the etching machine, the temperature must be maintained between 38 ℃ and 50 ℃. If it is right or wrong, the full-automatic model and specification must be adjusted manually, and the model and specification that can be fully automatic heating can save this trouble.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

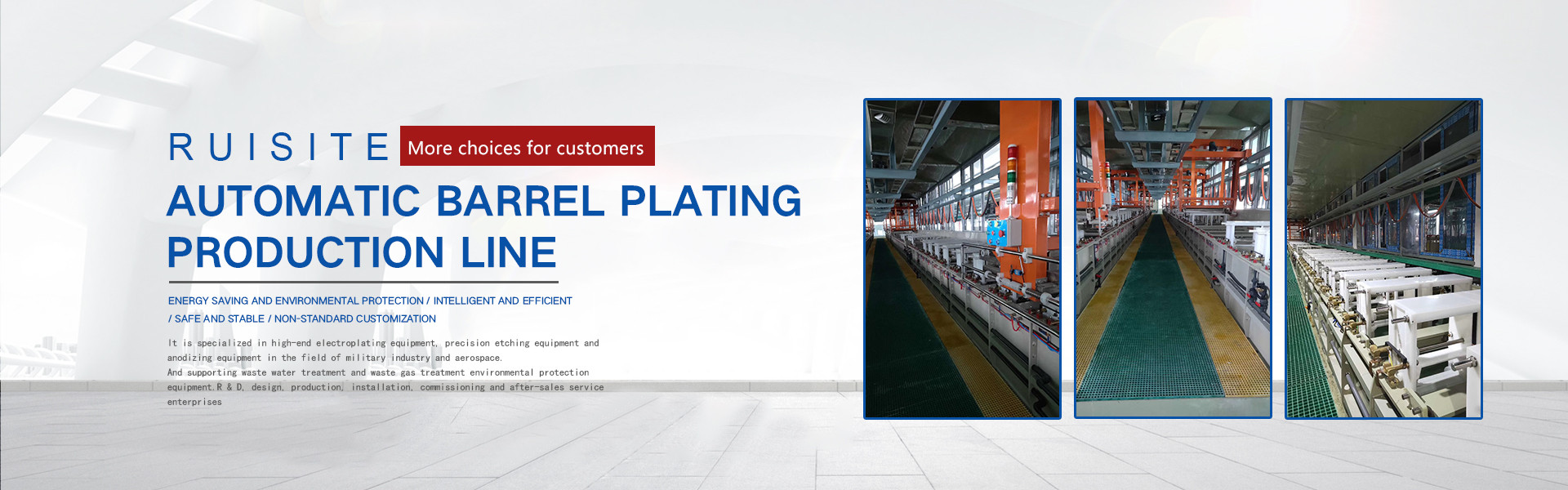

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

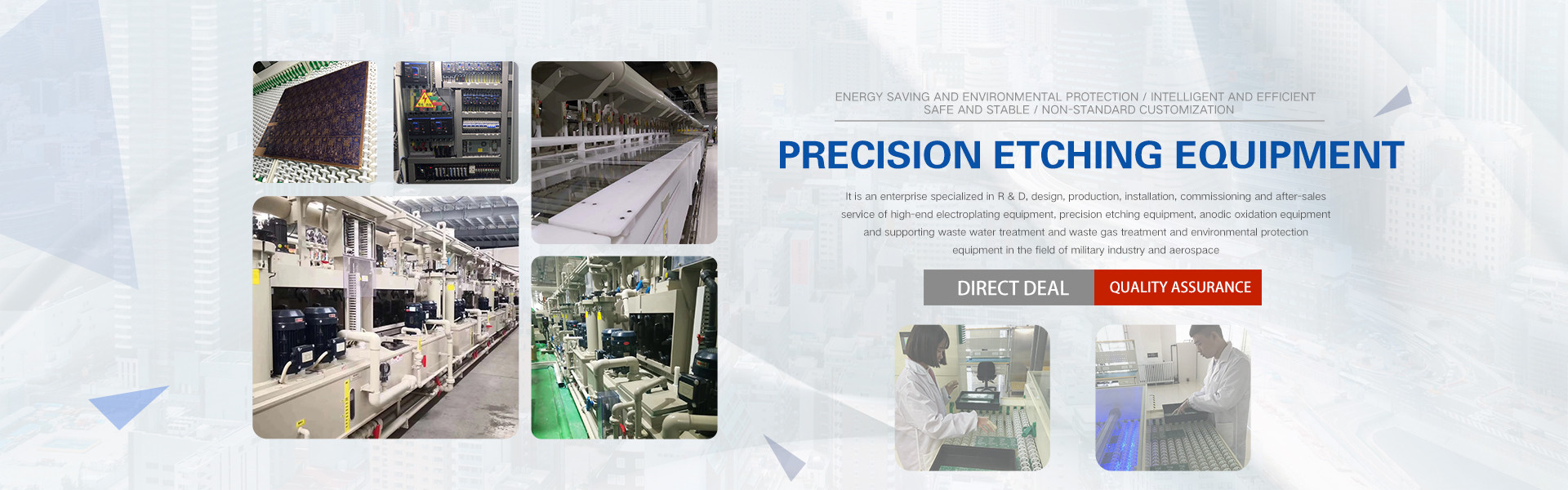

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords