The cold storage etching technology of hardware etching equipment manufacturers is a more complex replica technology based on the cold storage cracking technology. If the temperature of the cracked sample rises slightly, the ice in the sample is lifted in a vacuum pump, and the surface relief pattern shows the ultrastructure of the cytoplasm.

After a lot of dry ice sublimation, platinum carbon replica was carried out on the surface of the relief pattern, and the biotechnology was removed in the corrosive aqueous solution. The replica was cleaned up by re steaming water for several times, and then it was fished on the Internet for transmission electron microscope observation.

Technical advantages:

Therefore, the development trend of the cold storage technology is to combine the cold storage technology with the cold storage technology.

Its advantages depend on:

1. According to the cold storage, the microstructure of the sample can be close to the living condition;

2. After the sample is cracked and etched in cold storage, the microstructure of different fracture surfaces can be observed, so that the membrane structure and the structure of inclusion in somatic cells can be studied scientifically;

3. The replica film of the sample etched in cold storage was prepared by platinum and carbon plating. It has a strong sense of layering and can withstand negative electrons of ion beam and long-term storage.

Technical defects:

Hardware etching equipment manufacturers emphasize that its defects are: cold storage can also lead to human factors damage; cracking surface often results in the sensitive position of the sample structure, so there is no arrival station selection.

- Home page

-

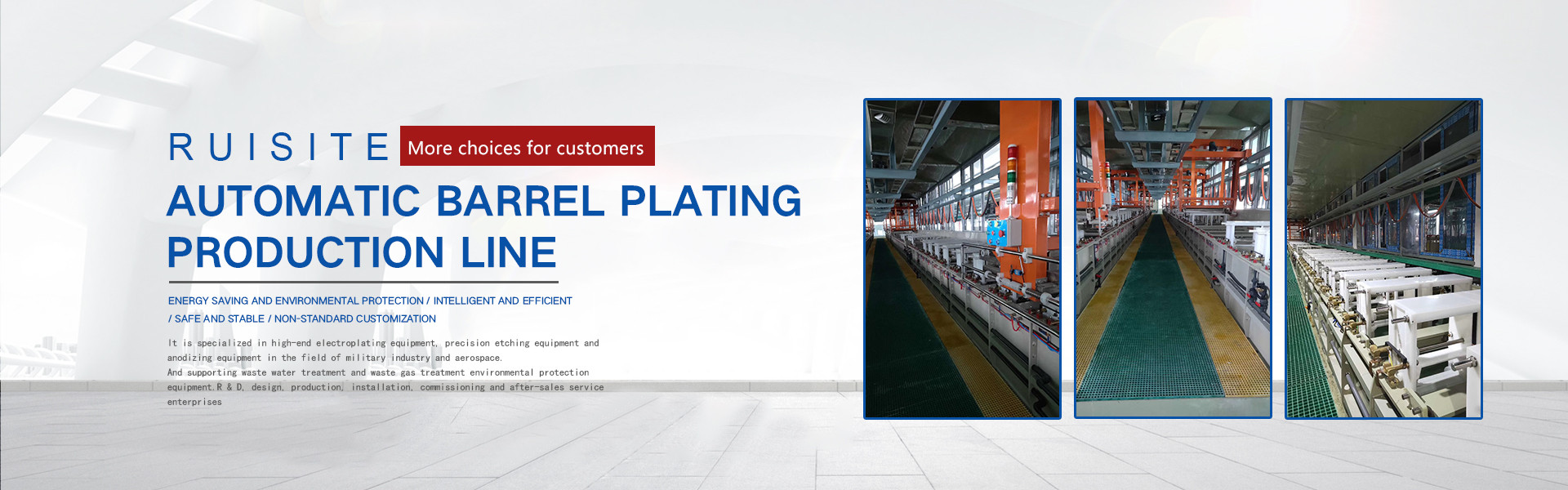

High end electroplating equipment

- Automatic galvanizing production line

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

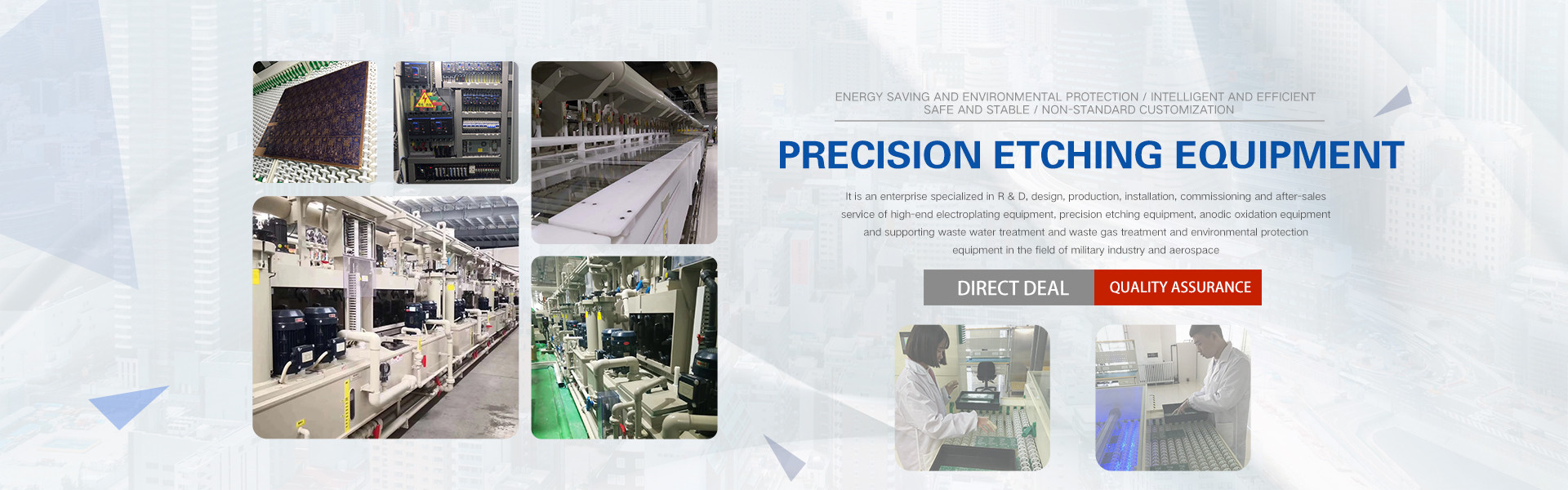

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords