It is the key step to obtain high-quality coating. In the pre plating process, the main machines and equipment commonly used include grinding, grinding and polishing machine, brush milling machine and automatic sandblasting machine Roll milling machine and various fixed fixed slots, electroplating solution is the main processing technology in the whole production process.

According to the provisions of the parts, one or more kinds of single metal materials or aluminum alloy electroplating processing technology are purposefully selected to carry out electroplating or dipping and other production processing on the parts, so as to achieve the purpose of corrosion resistance, wear resistance and beautiful appearance. The commonly used machines and equipment in the electroplating solution process mainly include various fixed fixed tanks, barrel plating tanks, hangers, electric hanging baskets, and the post plating treatment process is zero Grinding and polishing, polishing, passivation, coloring, boring, closed type, dehydrogenation and other work are carried out. According to the requirements, one or more processes are used to make the parts meet the quality requirements. The common machines and equipment for the post-treatment process mainly include grinding, grinding and polishing machines, various fixed fixed grooves, etc.

Electroplating refers to a surface production and processing method in which the positive ions of the metal to be electroplated are deposited on the surface of the base metal material according to the actual effect of the electrolysis method in the acid salt solution with the metal to be plated as the negative electrode. The function of the coating is different from that of the base metal material and has new characteristics It is a protective coating, decorative art coating and its functional coating.

Basic concept of electroplating: product R & D, overall planning, manufacturing, marketing and service of electroplating equipment and ultrasonic cleaning equipment are integrated. Electroplating is a kind of Photoelectrocatalytic process and an air oxidation-reduction process. The basic process of electroplating is to immerse the parts in the aqueous solution of metal salt as the negative electrode, and the metal sheet as the anode oxidation. After connecting the DC stabilized power supply, the required coating is deposited on the parts.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

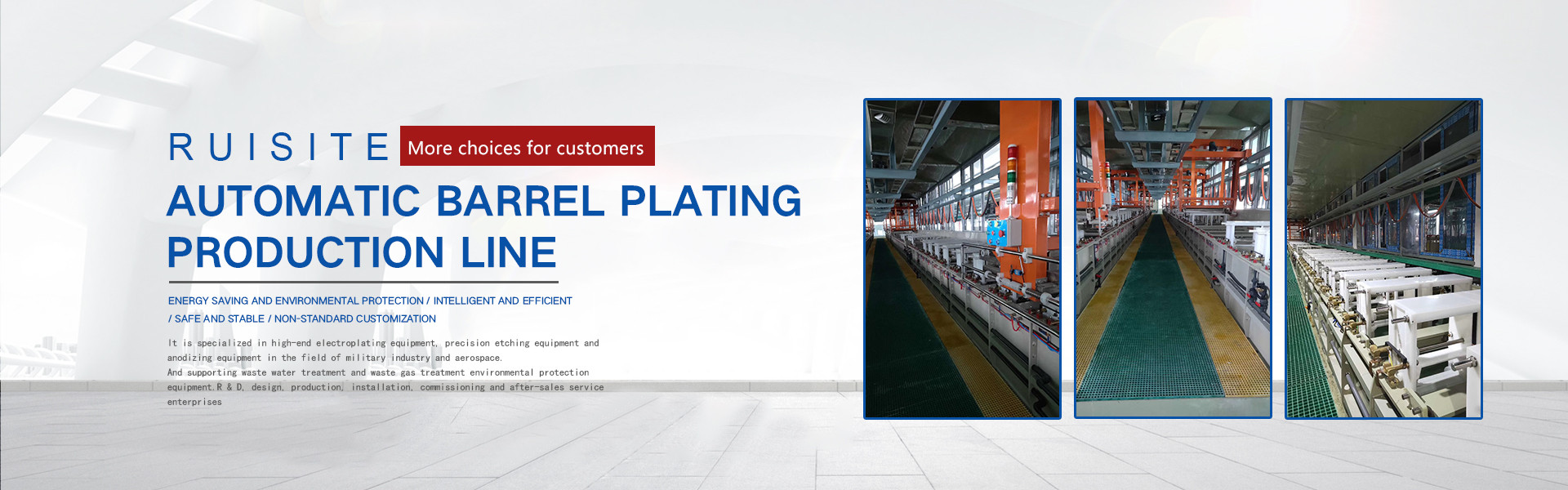

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

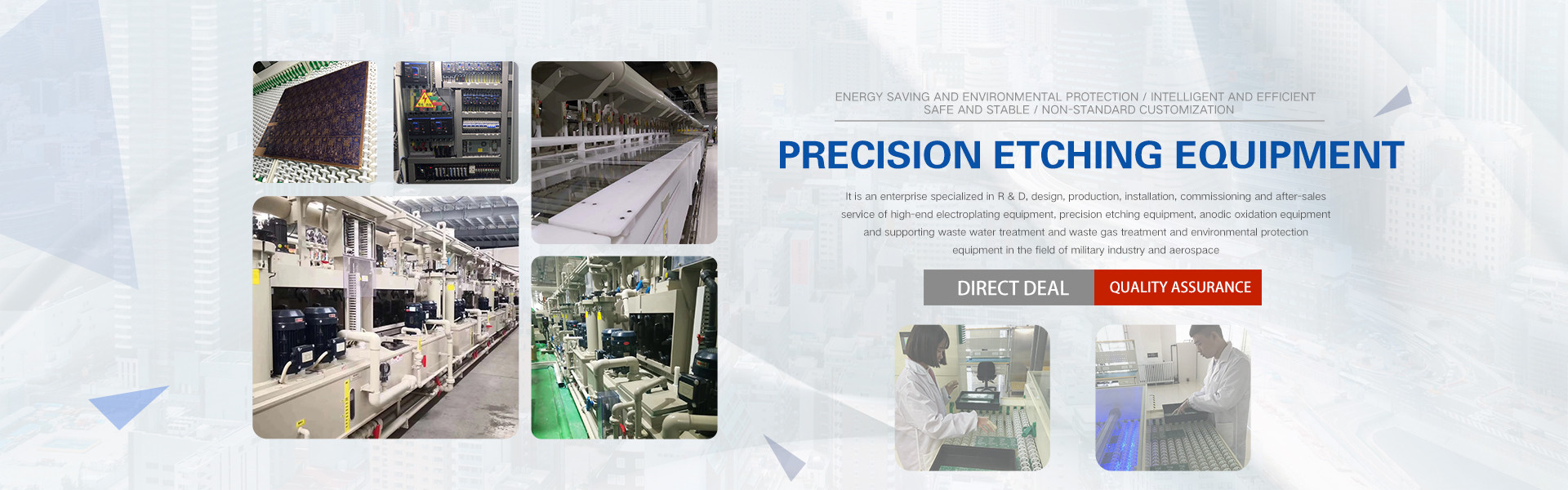

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords