Automatic galvanizing and electroplating equipment

中文(簡體)

中文(簡體)

To achieve quality, ingenuity to create our own brand

Many customers witness together

Forge ahead, blaze new trails, persevere in quality

It has strictly passed the national environmental protection inspection, all environmental impact assessment procedures, four major environmental assessment parameters of waste gas, waste water, noise and solid waste; the pickling workshop is completely c

50% + export to 20 + countries in Europe, South America, Japan, South Korea, Middle East and Southeast Asia; while meeting your product demand, we will design the overall scheme of steel pipe manufacturing and subsequent processing and manufacturing for y

11 R & D team, with 1% of annual output value annually; complete whole process production line, piercing, pickling, finishing rolling, cold drawing, straightening, flaw detection, tensile test and other testing equipment and machining; automatic numerical

The technical team can effectively solve all kinds of problems in the use of steel pipes and provide all-round technical support; one to one VIP service experience with one-to-one follow-up visit is carried out to track the use of products.

Your attention is our driving force

It is the key step to obtain high-quality coating. In the pre plating process, the main machines and equipment commonly used include grinding, grinding and polishing machine, brush milling machine and automatic sandblasting machine Roll milling machine an

more

The quick removal nozzle of etching machine can quickly separate the nozzle body and nozzle without any special tools; this kind of convenient and efficient design scheme can complete the rapid removal and replacement of the nozzle, so the hardware etchin

The traditional plating process of electroplating equipment generally includes non-ferrous plate bottom plating, upper layer plating, laser plating, secondary plating, stripping varnish and spraying protective film; while plastic plating refers to the pro

The key technologies of electrochemical corrosion pretreatment are: light induction etching, ink printing, sticking self-adhesive label. Each processing technology has its own advantages and disadvantages.

Before printing, we should not only prepare the suitable printing ink, but also prepare the hue and packaging printing characteristics according to the necessity, so as to consider the necessity of packaging printing. Hardware etching equipment manufactur

How to choose electroplating equipment? The selection of electroplating equipment is particularly important to ensure the quality of electroplating products and improve productivity, such as suspension electroplating production line, ring electroplating p

Due to its environmental protection, simple manufacturing and processing technology, low maintenance cost and other advantages, laser has become the preferred choice of most manufacturers.

15years of industry experience

Hundreds of customers witness

Thousands of customized equipment

Electroplating and etching products

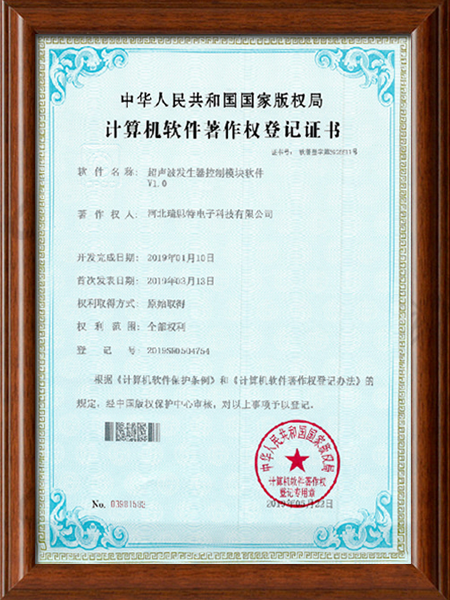

Product certification

Hebei Ruisite Electronic Technology Co., Ltd. is a cooperative unit of China Electronics Technology Group's 54th and 13th institutes, specializing in the R & D, design, production, installation, commissioning and after-sales one-stop service of high-end electroplating equipment, precision etching equipment, anodizing equipment, hardware etching machine and supporting wastewater treatment and waste gas treatment environmental protection equipment in the field of military industry and aerospace Industry. Our company continues to absorb the world's advanced surface treatment technology, combined with domestic and foreign market demand, to create a variety of different fields, different types of special electroplating equipment, etching machine equipment. The business covers military chip, integrated circuit electroplating, microwave, Beidou navigation transmission signal, military radar antenna remote sensing and telemetry, booster electroplating, involving gold, silver, copper, tin, nickel, chromium plating and other electroplating equipment and precision etching machine. It includes foreign military projects, such as high-end electroplating equipment and precision etching project of Bangladesh army, electroplating equipment project of Nigerian military, electroplating project and etching machine project of Vietnamese army.

contact number

Scan wechat