Before printing, we should not only prepare the suitable printing ink, but also prepare the hue and packaging printing characteristics according to the necessity, so as to consider the necessity of packaging printing. Hardware etching equipment manufacturers to match ink, first to estimate the relative ink consumption, so that the appropriate amount of ink. Especially for the two-liquid reaction printing ink, the ink mixing amount should be estimated according to its dry solid rate and packaging printing rate.

1. Hue in the development of printing ink color deployment, one is to pay attention to the light source on the printing ink color. Generally, the color should be developed in the sunlight, and the hue is more. And in the human light source color, you need to choose a better color as the light source, the actual color effect of fluorescent lamp is worse. When preparing printing ink, we should choose the color closer to the color, and then according to the addition of a small amount of other hues, we can get the required tone. The use of multicolor printing ink should be minimized. As the color saturation of commonly used printing ink is more, the gray level of intermediate color is higher and the hue is darker, which also makes the preparation of printing ink difficult to grasp. In the actual ink matching, you should roughly define the color of the color, select the relative printing ink, and then slowly add auxiliary ink. When adding dark brown ink, you should pay attention to add gradually, do not need to add too little at a time, otherwise it is very easy to cause consumption, and make the preparation continue several times.

2. Adjustment of packaging and printing characteristics in packaging printing, due to the numerous factors such as printing process materials, natural environment standards, wire mesh and so on, many printing inks can not be considered without preparation. Therefore, it is necessary to carry out appropriate preparation for the packaging and printing characteristics before application. In general, it is mainly based on adding neutralizer to improve its packaging and printing characteristics. If the mesh number of wire mesh is high and the drying rate should be slow, a small amount of anti drying agent can be added. However, when coarse screen packaging printing, the viscosity should be slightly higher, and the drying rate should be slightly faster, so the appropriate amount of drying agent should be added. Hardware etching equipment manufacturers in the addition of neutralizer to carry out the preparation, must be stirred evenly, the amount of its use must be moderate, otherwise the actual effect is likely to outweigh the loss.

- Home page

-

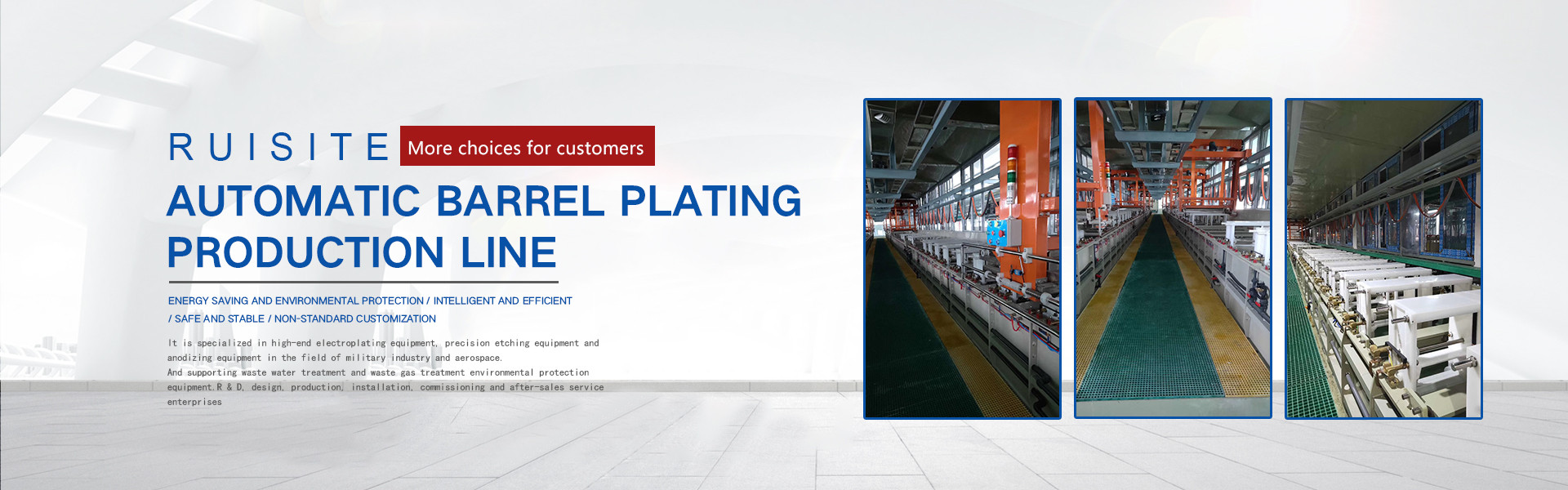

High end electroplating equipment

- Automatic galvanizing production line

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

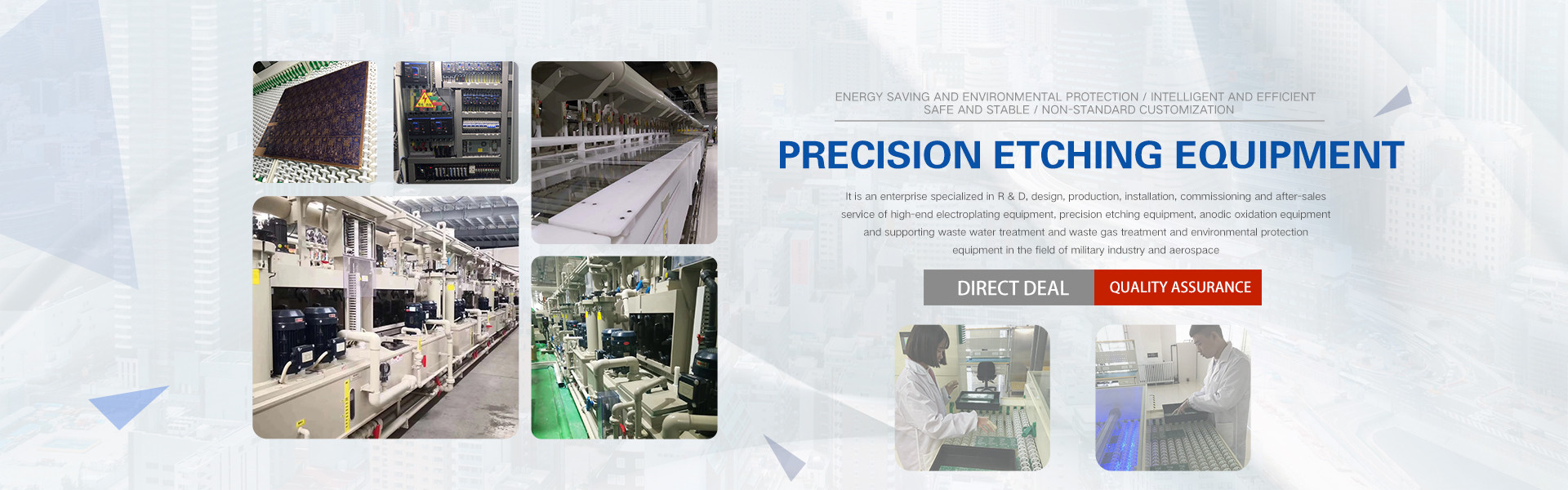

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords