Nowadays, many industries use etching more. There are some differences between the etching of laminated glass and the etching of metal materials. What is the actual difference between the two? Manufacturers of hardware etching equipment will give you a simple analysis.

The etching of laminated glass is different from that of metal material. The corrosion resistant layer should be considered in the etching of laminated glass. The traditional way of corrosion-resistant coating is to use paraffin to melt in the pot until boiling. After cooling to the edge of the film, brush the wax out of the laminated glass with a soft brush while it is hot, and then draw the wax layer by hand. It is obvious that this kind of method is no longer suitable for the necessity of manufacturing.

At the present stage, the anti-corrosion printing material has been generally selected. According to the ink printing, the corrosion-resistant layer of the text is obtained immediately by pressing it on the laminated glass. The commercial anti-corrosion printing material is 8200 series product laminated glass anti-corrosion printing ink. The printing ink has good anti-corrosion ability, and its appearance is dark blue and viscous. It takes 24 hours to dry at room temperature after screen printing, and 2 hours to dry at 75 ° C. The etching solution is put into the etching machine. According to the selection of 1:3 hydrochloric acid solution, there are 40% hydrochloric acid solution: 98% sulfuric acid = 9:1 solution.

Hydrochloric acid has very strong corrosion, hardware etching equipment manufacturers should pay attention to the natural ventilation of the natural environment and work safety protection. When the etching machine etches to the required depth, clean it with cold water to get clear and transparent etched text.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

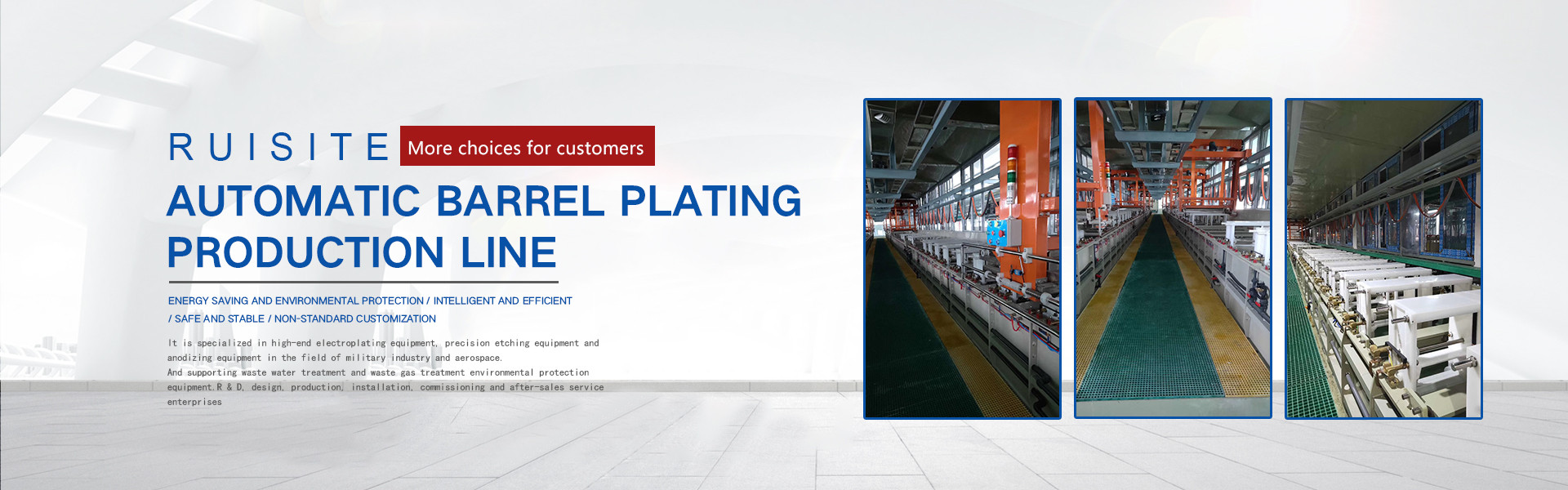

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

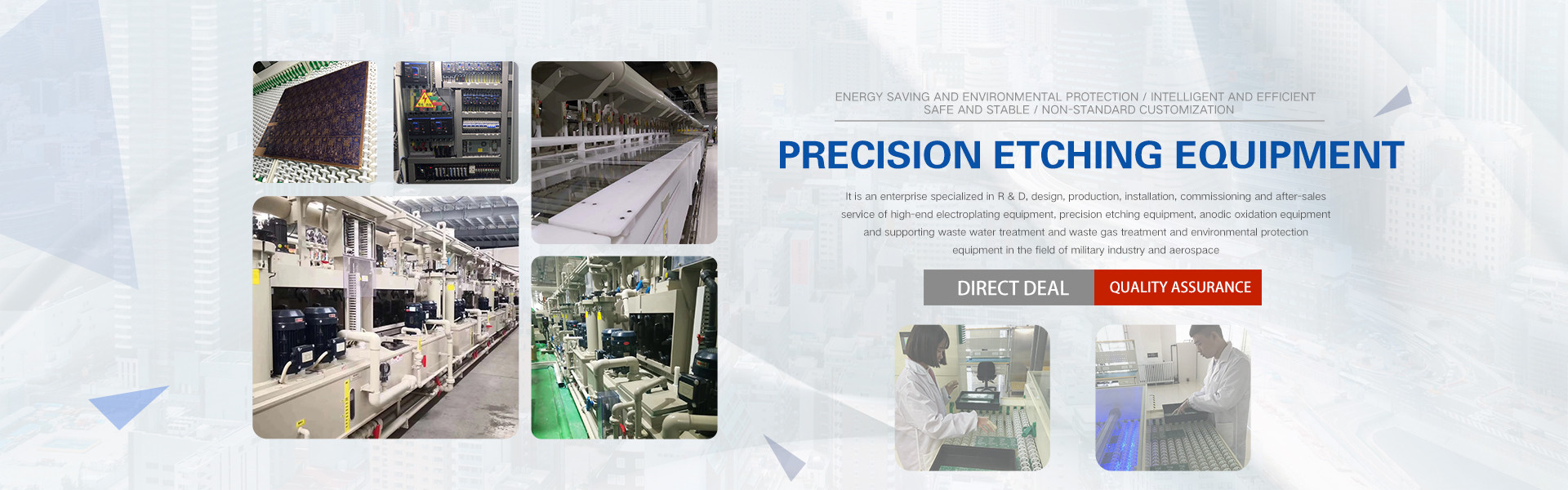

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords