With the development of PCB industry, the impedance requirements of all kinds of wires are becoming higher and higher, which inevitably requires more strict control of wire width. In order to make the engineering management personnel of Rongxin company, especially the process engineers who are responsible for the etching process to have a certain understanding of the etching process, this training material is written in order to help production management and monitoring, and improve the product quality of our company. (this textbook explains the etching process based on the equipment)

2. Basic principle of etching machine

1) Purpose of etching

The purpose of etching is to etch the unprotected non-conductor part of the printed circuit board made by the previous process to form a circuit.

There are inner layer etching and outer layer etching. Acid etching is used for inner layer, wet film or dry film is used as resist; alkaline etching is used for outer layer, and tin lead is used as resist.

2) Basic principle of etching reaction

1、 Acid copper chloride etching solution

1. Characteristics

- the etching speed is easy to control, and the etching solution can achieve high etching quality in a stable state

- high copper corrosion

- the etching solution is easy to regenerate and recover

2. Main reaction principle

In the process of etching, Cu2 + is oxidable, which oxidizes the surface copper into Cu +: Cu + CuCl2 → 2cucl

In the presence of excess chloride ions, soluble complex ions are formed

2CuCl+4Cl-→2[CuCl3]2-

With the reaction going on, there are more and more Cu + and the ability of copper etching decreases. It is necessary to regenerate the etching solution to change Cu + into Cu2 +. The regeneration methods are as follows: regeneration with oxygen or compressed air (low reaction rate), chlorine gas regeneration (fast reaction but toxic), electrolytic regeneration (copper can be directly recovered, but the equipment and high power consumption need to be electrolytic regeneration), sodium hypochlorite regeneration (high cost, dangerous itself), hydrogen peroxide regeneration (fast reaction rate, easy to control)

Reaction: 2cucl + 2HCl + H2O2 → 2cucl2 + 2H2O

Automatic control adding system: through controlling etching speed, adding proportion of hydrogen peroxide and hydrochloric acid, specific gravity and liquid level, temperature and other items, automatic continuous production can be achieved.

Our company adopts this regeneration method.

2、 Alkaline ammonia etching solution

1. Characteristics

- no reaction with tin and lead

- easy to regenerate, low cost and easy to recover

- fast copper etching speed, small side etching, high copper dissolving ability and easy control of etching rate

2. Main reaction principle

Cu+Cu(NH3)4Cl2→2Cu(NH3)2Cl

4Cu(NH3)2Cl + 4NH3H2O + 4NH4Cl + O2 → 4Cu(NH3)4Cl2+6H2O

The above two reactions are repeated, so it is necessary to have a good air extraction to form a negative pressure of spray, so that the oxygen in the air and the liquid medicine are fully mixed, which is conducive to the etching reaction. Pay attention not to exhaust too much, otherwise the consumption of ammonia will increase

In the alkaline environment, divalent copper ions are easy to form copper hydroxide precipitation, so it is necessary to add excessive ammonia to form stable ammonia copper wrong ion group; excessive ammonia makes the unstable Cu (NH3) 2Cl generated in the reaction produce stable Cu (NH3) 4cl2, which makes the reaction continue.

In the production process, automatic control through monitoring pH value, specific gravity, adding ammonia water and new liquid, so as to achieve the purpose of continuous production.

3. Etching process and principle

1、 Acid copper chloride etching

1. Process flow

2. Process principle

- developing

Definition: using the weak basicity of sodium carbonate, the part of the dry film that has not been ultraviolet radiation is dissolved with sodium carbonate solution, and the part that has been irradiated by ultraviolet radiation and polymerized is retained.

- principle

CO3-2 + ResistCOOH HCO3- + Resist COO-

Co3-2 is mainly Na2CO3 or K2CO3

Resisttooh is the reaction functional group in dry film and ink. Co3-2 is used to neutralize the carboxyl group (COOH) in the inhibitor to form COO - and HCO3 - to form anion group and peel off the inhibitor.

- etching

Definition: dissolve dry film (wet film) and exposed copper surface with acid copper chloride solution corrosion, this process is called etching.

Influencing factors: mainly the content of Cl -, Cu +, solution temperature and Cu2 + concentration.

- melatonin

Solution: NaOH 3 + / - 0.5%

Defoamer 0.1-0.2%

Definition: remove the protective film from the circuit to expose the processed circuit. The factors affecting the effect of film Fading: temperature and speed of film fading, concentration of liquid medicine

Attention: low temperature, slow speed and low concentration of solution will lead to unclean film fading; high concentration of liquid medicine will lead to oxidation of board surface.

The nozzle of the desalting section should be cleaned in time to prevent debris from blocking the nozzle and affecting the quality of the fil

2、 Alkaline etching

1. Process flow

Note: the whole hole process is only applicable to the sinking of gold plate

2. Process principle

- melatonin

Definition: the film covered on the circuit board surface is removed with the film fading solution to expose the copper surface without wire processing. The dry film after electroplating is dissolved or partially flaked off under the alkaline film fading solution. Our company uses 3% ± 0.5% sodium hydroxide solution. In order to maintain the effect of the medicine solution, it is necessary to pay attention to the filtering effect, timely filter to remove the flake dry film fragments, and prevent blocking the nozzle

Note: the chemical solution and control are the same for the inner and outer layer fading section, but the dry film thickness of the outer layer is about 1.5mil. After pattern electroplating, the sum of copper thickness and tin thickness usually exceeds 1.5mil. It is necessary to control the current parameters of graphic electroplating to prevent film clamping, and control the stripping speed to prevent short circuit due to unclean fading film.

- etching

Definition: use etching solution to remove the excess bottom copper and leave the thickened circuit.

Control: with the reaction going on, ammonia in the solution is decreasing and copper ions are increasing. In order to maintain the copper etching rate, it is necessary to maintain the stability of the solution. Our company controls the automatic addition of ammonia and new liquid through pH meter and hydrometer. When the pH value is low, add ammonia water; when the specific gravity is high, add new liquid. In order to make the copper corrosion reaction more rapid, the etching solution is added with additives, such as:

a. The accelerator can accelerate the oxidation reaction and prevent the precipitation of cuprous ion.

b. Bankingagent reduces lateral erosion.

c. The depressor can inhibit the dispersion of ammonia at high temperature, inhibit the precipitation of copper and accelerate the oxidation reaction of copper.

- new liquid wash

Using nh3.h2o and NH4Cl solution without copper ion to remove the residual liquid and the reaction product Cu (NH3) 2Cl, which is extremely unstable, is easy to form precipitation.

- whole hole

Remove the palladium ion adsorbed in the copper precipitation process in the non plating through-hole to prevent gold deposition in the gold precipitation process

- desalting

The main component of copper protective agent is nitric acid, and the tin lead layer on the circuit is removed to expose the circuit

4) Explanation of terms

Pool effect

In the etching process, when the circuit board passes through the etching machine horizontally, due to the gravity effect, the fresh liquid medicine on the board is blocked by water, and can not effectively react with the copper surface, which is called pool effect. This is not the case below.

etching factor

In the process of etching, the etching solution not only has the effect of etching downward, but also has an effect on both the left and right directions. The ratio of etching width to etching depth is called etching factor.

Etching factor = D / C

Undercut=(A-B)/2

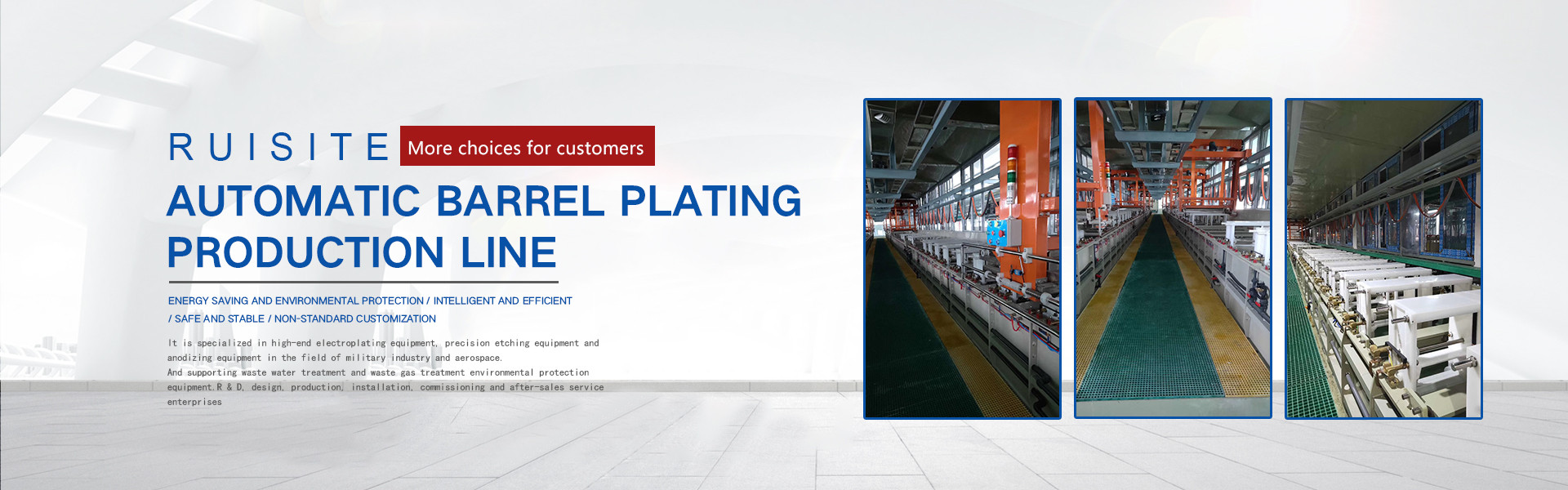

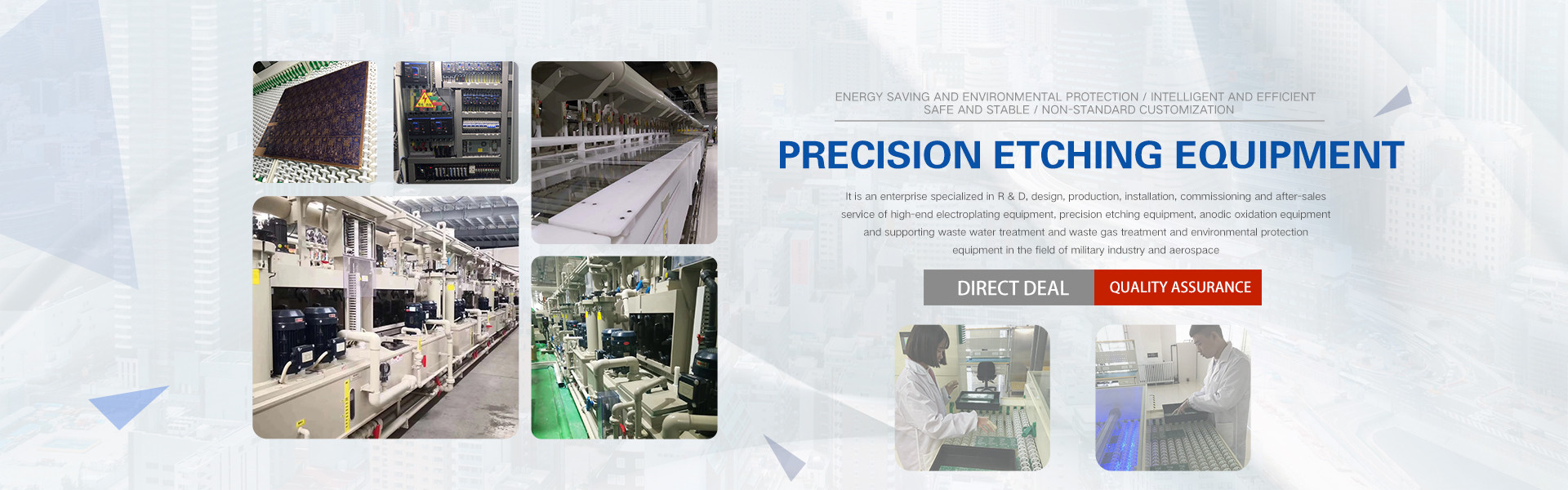

5) Equipment

- horizontal line equipment is used for both internal and external layers.

- for alkaline etching, in order to increase the etching speed, the temperature needs to be raised to above 46 ℃, so there is a large amount of ammonia odor, and proper ventilation must be provided; if the exhaust air is too large, it will be waste to exhaust the ammonia gas. A throttle valve is added in the exhaust pipe to control the strength of the exhaust air.

- no matter what kind of etching solution, high-pressure spray should be used; in order to obtain a more neat line side and high-quality etching effect, the nozzle shape and spray mode must be strictly selected. However, no matter how to choose, it follows a basic theory, that is, the more fresh etching solution is exposed to the copper surface to be etched quickly.

- the shape of the nozzle is conical (empty cone, solid cone), fan-shaped, etc. our company adopts fan-shaped nozzle. Compared with the conical nozzle, the design of is fan nozzle. Pay attention to the installation angle of the collecting pipe, and spray the plate into the etching groove by 30 degrees. The second group of collecting pipes is different from the group ratio, because the spray liquid will reduce the effect of spraying when they cross each other, so this situation should be avoided as far as possible.

- there are horizontal, vertical and oblique installation of the collector in the etching groove compared with the forward direction. There are two installation methods adopted by our company (see the figure below). But the swing direction is perpendicular to the transportation direction.

- etching quality is often limited by the pumping effect, which is why the plate

The sub front-end part often has the overtch phenomenon, so the device design has the following

consider:

a. The board is thinner, the line side is down, the thicker line is up

b. The upper and lower injection pressure of the nozzle is adjusted to compensate, and the difference is adjusted according to the actual operation results

c. The advanced etching machine can control the front several groups of nozzles to stop spraying for several seconds when the board enters the etching section

3. Technology improvement

1) Brief introduction of production line

1. Acid etching of inner layer

Machine operation parameters of punching, etching and melatonin production line

Standard of dressing change and tonic for flushing plate, film and film

2. Alkaline etching of outer layer

A) TCM stripping and etching machine are used

Effective width: 620mm

Roller speed: 0 ~ 8m / min

Pressure: 2.5kg/cm2

Good electrical safety and mechanical protection.

B) . operating conditions

2) Production line maintenance

Daily maintenance of equipment

A. The more slagging, the chemical balance of etching solution will be affected, and the etching rate will decrease rapidly. So it's important to control the composition - especially pH, which can be too high or too low

B. Keep the nozzle free from clogging at any time. (the filtering system should be kept in good condition). Check the nozzle during weekly maintenance. If it is blocked, remove the blockage immediately.

C. Replace damaged nozzles and accessories in time

D. PH meter and specific gravity sensor should be calibrated regularly

3) Production precautions

1. Strictly control the concentration of stripping solution to ensure that the dry film can be withdrawn at a proper speed and size, and it is not easy to block the nozzle.

2. After stripping, the water washing pressure should be greater than 20psi, so as to remove the residual film between the coating and the bottom copper and attached to the plate surface.

3. The pressure of etching solution should be 18 ~ 30psi. If it is too low, it will not be etched completely. If it is too high, it is easy to break the protective film of the potion, resulting in excessive etching.

4) Analysis of factors affecting etching rate

1、 Acid copper chloride solution

There are many factors affecting the etching rate, mainly Cl -, Cu + content, solution temperature and Cu2 + concentration.

1. The influence of Cl - content

When the concentration of Cl - in copper chloride etching solution is high, Cu2 + and Cu + actually exist in the form of complex ions ([Cu2 + CL4] 2 -, [Cu + CL3] 2 -), so the preparation and regeneration of etching solution need Cl - to participate in the reaction. The following table shows the relationship between chloride solubility and etching rate.

It can be seen from the figure that:

- when the solubility of hydrochloric acid increases, the etching time decreases, but when the hydrochloric acid exceeds 6 N, the hydrochloric acid volatilizes greatly and causes corrosion to the equipment. With the increase of acid concentration, the solubility of copper chloride decreases rapidly.

When copper is etched in copper chloride solution, the resulting CuCl2 is not easily soluble in water, so a layer of cuprous chloride film is formed on the surface of copper, which can prevent the further reaction. The excess Cu - can combine with cu2cl2 to form soluble complex ion [Cu1 + CL3] 2 -, which dissolves from the copper surface, thus increasing the etching rate.

2. The influence of Cu + content

According to the etching reaction, univalent copper ions will be formed with copper etching, and a small amount of Cu + will significantly reduce the etching rate.

According to the nairns equation:

E - electrode potential at specified concentration

N is the number of electron gains and losses

Concentration of [Cu2 +] - divalent copper ion

[Cu +] - concentration of univalent copper ion

Relationship between Cu + concentration and redox potential

Relationship between redox reaction site and etching rate

It can be seen from the figure that the redox potential decreases with the increase of Cu + concentration. When the redox potential is 530 mu, Cu1 + concentration below 0.4g/l can provide ideal high and almost constant etching rate.

3. The influence of Cu2 + content

The relationship between Cu2 + content and etching rate is as follows

When Cu2 + is low, the reaction is slow, but when Cu2 + reaches a certain concentration, the reaction rate also decreases.

4. The effect of temperature on etching rate

With the increase of temperature, the etching time is shorter, generally in the range of 40-55 ℃. When the temperature is high, it will cause excessive volatilization of HCl, resulting in the imbalance of solution proportion. In addition, higher temperature will also cause machine damage and corrosion inhibition layer damage.

2、 Alkaline ammonia etching solution

The pH value of etching solution, specific gravity (Cu2 + concentration), ammonia chloride concentration and etching solution temperature all have influence on the etching speed.

1. The influence of Cu2 + content

The etching rate is low and the solution control is difficult;

If Cu2 + is too high, the solution is unstable and precipitates easily;

- the concentration of Cu2 + should be controlled at 115 ~ 135g / L, and continuous production should be controlled by specific gravity.

2. The influence of pH value of solution

If the pH value is too low, it is unfavorable to the metal corrosion resistant layer; and the copper in the solution can not be complexed to form cuprammonium complex ion completely, the solution will precipitate and form mud like precipitation at the bottom of the tank. These precipitates can form a hard crust on the heater, which may damage the heater and block the pump or nozzle, making etching difficult.

- if the pH value is too high, ammonia in the solution will be supersaturated and free into the air to pollute the environment, and the side corrosion will increase.

3. The influence of ammonia chloride content

- it can be seen from the previous reaction that the regeneration of Cu (NH3) 2Cl requires the presence of excess NH3 and NH4Cl. If the ammonia chloride is too low, Cu (NH3) 2Cl can not be regenerated and the etching rate will be reduced.

- too high ammonia chloride causes the corrosion resistant layer to be eroded.

4. Influence of temperature

- the etching rate increases with the increase of temperature;

- if the etching temperature is too low, the etching speed will decrease, which will increase the side etching amount and affect the etching quality.

- when the etching temperature is high, the etching speed increases obviously, but the volatilization of ammonia increases, which pollutes the environment and increases the cost.

5. The influence of injection pressure

- the pressure of etching solution should be between 18 ~ 30psi. If it is too low, the etching will not be complete. If it is too high, the protective film of the solution will be easily broken, resulting in excessive etching.

5) Improved etching capacity

1、 It can reduce side erosion and edge protrusion and improve etching factor.

The results show that the side erosion causes the sharp edge, the side erosion and the protruding edge decrease, and the etching factor will increase; the excessive edge will cause the short circuit of the wire, because the sharp edge will break suddenly and form the electrical connection between the wires. Serious side erosion makes it impossible to make fine wires.

Factors affecting side erosion and improvement methods

Etching method: immersion and bubbling will cause larger side corrosion, splash and spray type side corrosion is smaller, especially spray type side corrosion is small.

Etching solution type: different etching solution chemical composition is different, etching speed is different, side etching is also different. Generally, the etching factor of alkaline copper chloride etching solution is larger than that of acid copper chloride etching solution. Liquid medicine suppliers usually add auxiliary agents to reduce side corrosion. Different suppliers add different auxiliary agents and different etching factors.

Etch transport rate: slow transport can cause serious side erosion. The faster the transport rate is, the shorter the plate stays in the etching solution, and the smaller the side erosion is. In the production process, try to increase the etching transport speed. PH value of etching solution: alkaline etching solution, when the pH value is higher, the side corrosion increases. Generally, the pH value is controlled below 8.5.

The specific gravity of etching solution: if the specific gravity of alkaline etching solution is too low, it will aggravate the side corrosion. Choosing the etching solution with high copper concentration is beneficial to reduce the side corrosion.

Bottom copper thickness: the larger the bottom copper thickness, the longer the plate needs to stay in the etching solution, the greater the side corrosion. In order to make compact and small circuit boards, use copper foil with low thickness as far as possible to reduce the copper plating thickness of the whole board.

2、 Improving the consistency of etching rate between plates

In the continuous production process, the more uniform the etching rate is, the more uniform the plate can be obtained, and the production is easier to control. Therefore, it is necessary to ensure that the solution is always in a state.

- choose the solution which is easy to regenerate and control the etching rate;

- selection of automatic control processes and equipment that provide constant operating conditions

- the stability of the solution is ensured by automatic addition

- the uniformity of solution flow is ensured by the swing of spray system or nozzle

3、 The uniformity of etching rate is improved.

The etching uniformity of the upper and lower sides of the plate and each part of the plate surface is determined by the uniformity of the etching liquid flow rate on the plate surface.

- due to the influence of pool effect, the etching rate under the plate is higher than that on the upper part, and the spray pressure at different positions can be adjusted according to the actual production situation. In the production operation, it is necessary to test and adjust the equipment regularly.

- the etching rate at the edge of the plate is faster than that in the middle of the plate. This problem can also be solved by adjusting the pressure. In addition, the swing of the spray system is also effective.

Common problems and improvement

6) Process potential and Prospect

With the development of PCB in the future, such as the production of flexible board and dense circuit board, corresponding measures will be taken, such as etching 1 / 3 to 1 / 2 of the bottom copper of the board after drilling, and then making PTH full board, dryfilm and graphic plating can reduce side corrosion, so as to ensure sufficient line width.

7) Production safety and environmental protection

Due to the use of strong alkali (such as NaOH), ammonia and other chemicals in the etching process, a large amount of odor is produced in the production process, and a large amount of waste liquid and waste residue are produced. Therefore, the ventilation should be strengthened and the waste liquid and waste residue should be transported away in time. At the same time, the etching liquid can be recycled.

中文(簡體)

中文(簡體)