1、 Principle of etching process

In a professional sense, the principle of etching refers to a controlled corrosion behavior of metal through a professional etching machine according to the design and process requirements. Through this controlled chemical processing, the design requirements of some special occasions can be met, which can not be achieved by traditional machining methods. Metal chemical corrosion, in more cases, refers to the chemical loss caused by the chemical damage of metal in the natural environment. Therefore, the widely accepted definition of metal corrosion is: the chemical loss behavior of metal caused by chemical or electrochemical interaction between metal and surrounding media. From this definition, all kinds of corrosion of metal is actually the chemical loss of metal. There are four kinds of language expressions of metal chemical loss: chemical corrosion, chemical etching, chemical milling and chemical texture etching. These four expressions can be understood from the following aspects:

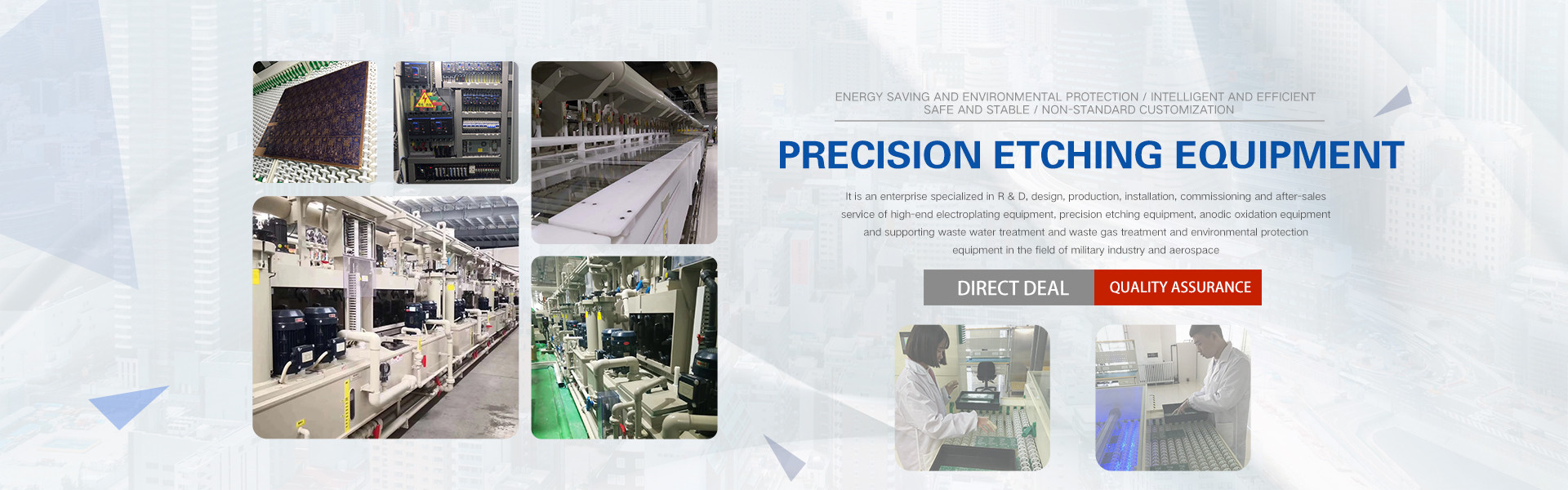

Chemical corrosion: chemical corrosion is a common phenomenon and process of metal chemical loss, including the damage and corrosion of metals in various corrosive environments, as well as the corrosion of controlled processing by chemical methods. From the whole process, it includes both uncontrolled corrosion and controllable etching. It is the general term of metal chemical loss and a kind of chemical loss behavior of metal in various chemical corrosion media. Many etching machine manufacturers, such as Hebei riste company, use this etching method.

2.Chemical etching: chemical etching is very targeted, which refers to controlled corrosion. It is a controllable processing method of metal through chemical methods. Chemical etching can be divided into chemical milling and chemical texture etching according to the surface effect after etching and the requirement of adding X.

3.Chemical milling: chemical milling has the same meaning as mechanical milling, but the processing method is different. Chemical milling requires that the surface after chemical etching should have as high surface smoothness as possible, as low surface roughness as possible, and as high etching accuracy as possible.

4.Chemical texture etching: chemical texture etching refers to the chemical etching of the surface, showing a certain roughness of the surface effect, and the size of this roughness can be adjusted in a certain range by controlling the chemical and physical indicators of the process. The chemical indicators include: the type of corrosive agent used and the concentration ratio between them; the physical indicators include: etching temperature, etching time and etching method.

2、 The specific process of chemical etching process is as follows:

Step 1: cleaning treatment: the purpose of FL is to clean all kinds of stains on the blank surface of the parts to be corroded, so as to ensure that the adhesion between the anti-corrosion layer and the metal surface is uniform and consistent, and the etching speed is uniform. The commonly used cleaning methods are: organic solvent cleaning, alkaline chemical cleaning, acid chemical cleaning, ultrasonic cleaning and electrolytic cleaning. D. in the process of use, it can be selected according to the type of metal materials and the pollution degree of parts surface.

Step 2: anti corrosion treatment: the purpose is to protect the surface that does not need to be corroded, so that the metal surface that needs to be corroded is completely exposed and corroded by the corrosive agent suitable for the metal material. This process requires that the anti-corrosion material should adhere firmly to the metal surface, and the anti-corrosion layer will not fall off during the whole corrosion process. The anti-corrosion treatment mainly includes: screen printing anti-corrosion technology, photographic chemical anti-corrosion technology, pad printing anti-corrosion technology, graphic electroplating anti-corrosion technology, laser lithography anti-corrosion technology and etching anti-corrosion layer technology.

Step 3: corrosion processing: it is the process of putting the corroded metal parts into the corrosion tank after making anti-corrosion pictures and texts according to the drawing requirements. In this process, the main control: corrosive concentration, corrosion temperature, etching time and other metal corrosion processing according to the requirements of the drawing can be divided into five basic types, namely: overall corrosion, selective corrosion, multi-step corrosion, taper corrosion and chemical cutting blanking. Metal overall corrosion + anti-corrosion treatment is required. Parts can be processed after cleaning.

Step 4: remove the anti-corrosion layer: after the corrosion of the parts is qualified, use solvent, alkali or other cleaning agents to remove the anti-corrosion layer on the surface of the parts.

中文(簡體)

中文(簡體)